|

Cheshire Pump Company

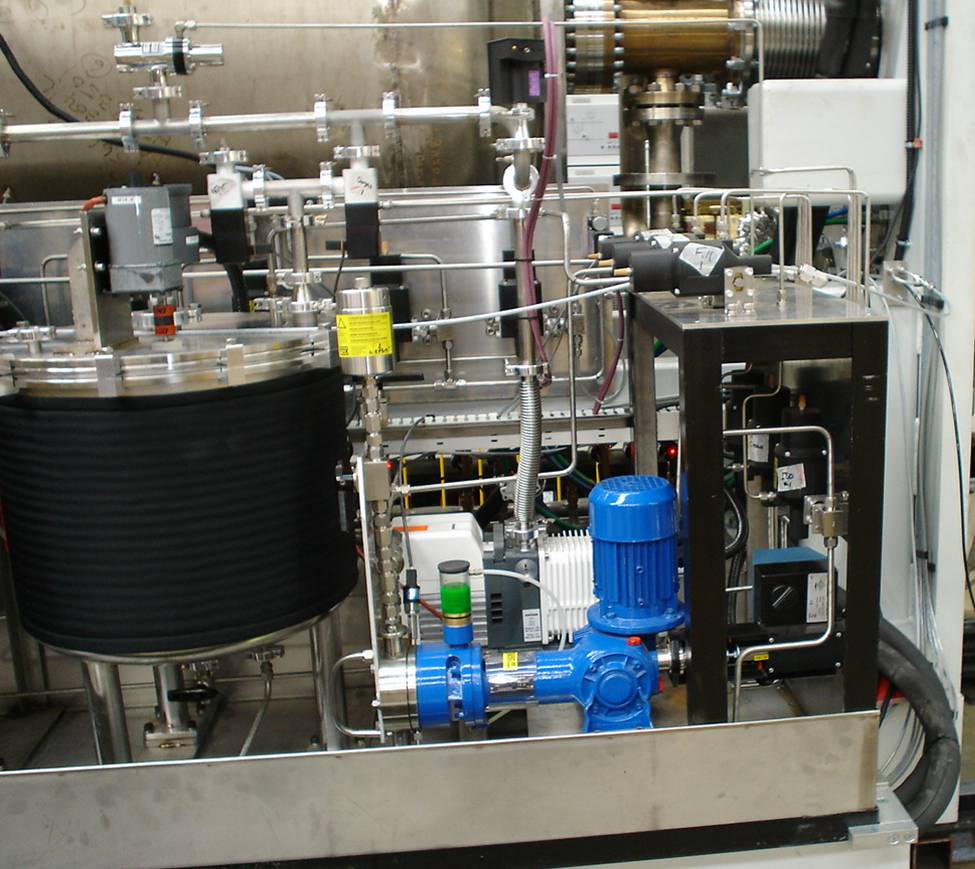

SEKO Positive displacement pumps

|

|

HomeTechnologyPlant design and managementTech TalkLarox (Flowrox) Pinch ValvesLarox (Flowrox) PVEG Pinch valvesLarox (Flowrox) Peristaltic PumpsLarox (Flowrox) Progressive Cavity PumpsLarox (Flowrox)Backflow Prevention ValvesLarox (Flowrox) rotating disc valveLarox (Flowrox) Knife Gate ValvesSEKO Positive displacement pumpsSubmersible PumpsContact Info

|

Pumps Valves

Expertise Service

UK 01625 560 060 (International +44 1625 560 060) Great News, from June 1st 2011 we have moved to larger premises (address below)

High

viscosity fluids generally need more energy to move them than low viscosity fluids Dynamic Viscosity is stated in Centipoise (cP) it is commonly used because water at a temperature of 20°C has a viscosity of 1.002 Centipoise, most published pump test and performance data is stated "in water" Below about 300cP, and dependant on fluid type and system detail, roto-dynamic (RD)pumps are generally used eg centrifugal pumps, submersible pumps

|

Positive displacement (PD) pumps are used for fluids with viscosities usually greater than about 300 centipoise

Positive displacement (PD) pumps are used for fluids with viscosities usually greater than about 300 centipoise  Metering pump flow-rates can be varied by changing

the

Metering pump flow-rates can be varied by changing

the